With its high hardness and superior mechanical properties and high temperature resistance, Preventa PVD coating is ideal for chip removal applications, especially under harsh conditions.

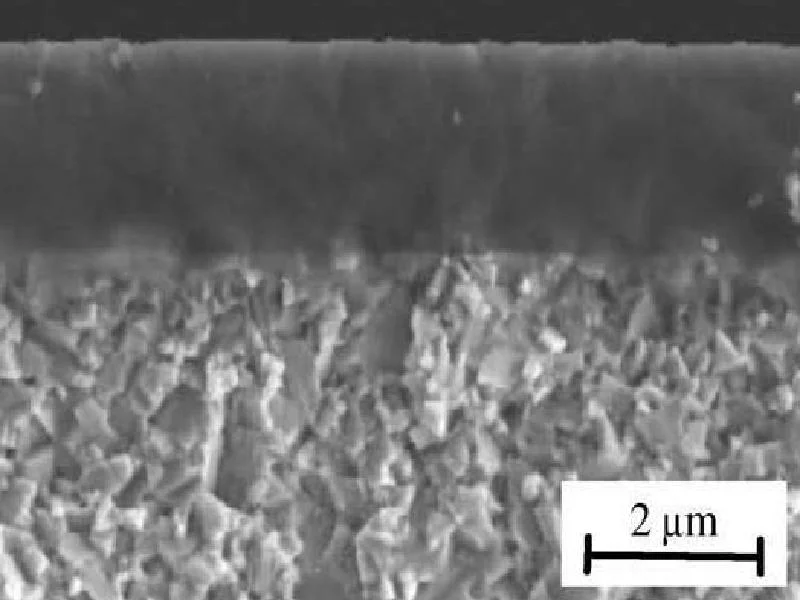

Preventa features a nanocomposite coating. While the grain sizes of conventional PVD coatings are in the range of 30-80 nanometers depending on the type of coating, the grain sizes of nanocomposite coatings are usually around 10 nanometers. For this reason, the columnar grain structure of conventional PVD coatings seen in the electron microscope cross-section photographs is not seen in nanocomposite coatings; the structure has an amorphous-like appearance. Cross-sectional photographs of a PVD coating with columnar structure, and of a nanocomposite coating are shown below.

Nanocomposite coatings can be used, without loss of hardness and chemical degradation, even at operating temperatures above 1000 ° C. Thanks to these features, Preventa coating, with nanocomposite properties, and developed by TITANIT, can be successfully used in dry cutting applications during which very high cutting temperatures occur, and cutting tools used in the processes of hard tool steels at fast rate, and applications during which high temperatures are formed on the tools.

Properties and application area

- In a nanocomposite structure, very high cold and heat hardness

- Suitability for heavy chip removal processes at very high speeds

- Suitability for machining of hard workpieces

- Dry chip removal processes

| Technical Properties | |

| Color | Bronze |

| Composition | TiSiN Based |

| Oxidation temperature | 1100 °C |

| Hardness | 4200 HV |

| Friction co-efficient | 0,50 |

| Coating thickness | 1 – 4 μm |