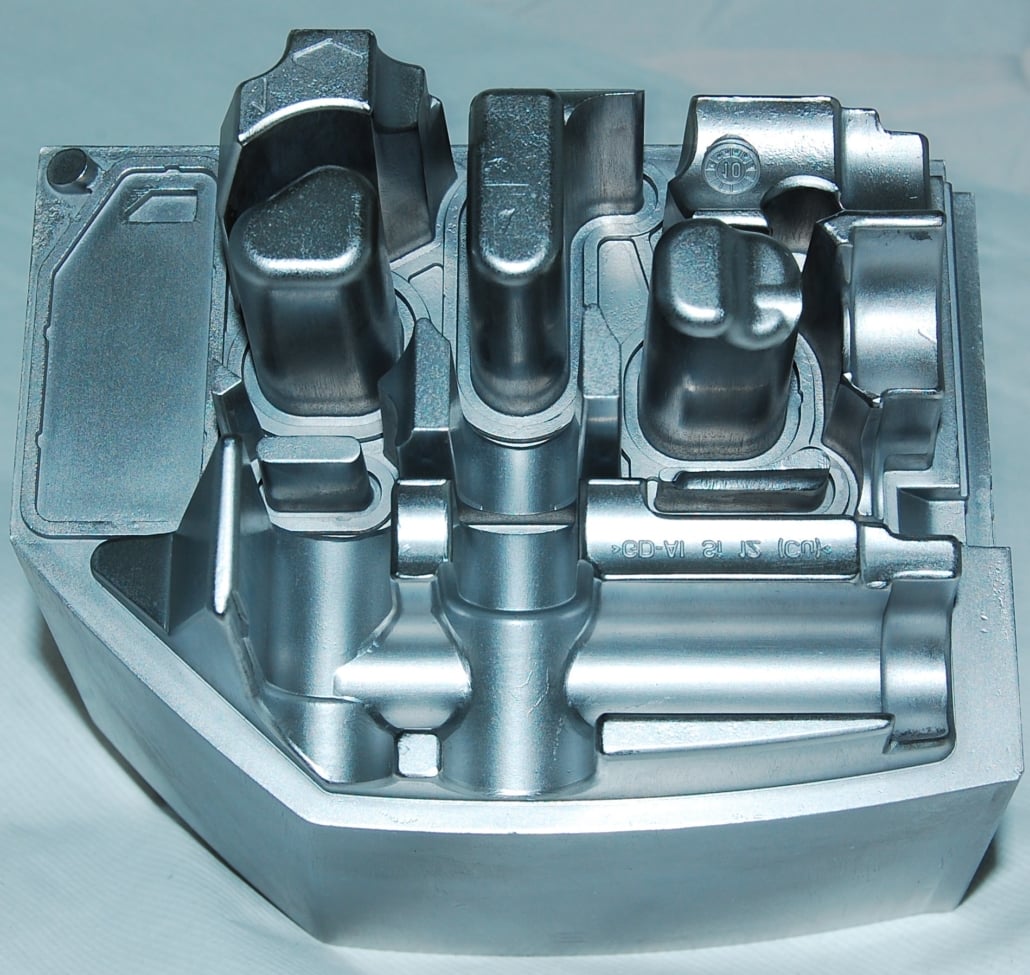

Moldex Extra chromium nitride (CrN) based coating is a general purpose PVD coating with high chemical stability and hardness as well as low friction co-efficient and heat conduction. It is extremely resistant to winding wear especially in spinning, form, deep drawing and rolling molds. Since it is resistant to high temperatures and chemical media, it is also successfully applied in plastic injection molds. Thanks to its high abrasion resistance and advanced surface regime, it is used successfully in cutting tools and special guides that process non-ferrous soft metals such as copper, aluminum, brass, wood, plastic. Since its internal stress is low, it can be applied at high thickness (up to 10 microns).

Properties and application area

- Suitable for spinning-forming molds through its very low friction co-efficient

- Suitable for tools used in the machining of non-ferrous soft workpieces

- Applicability up to 10-micron thickness thanks to its high toughness

- Excellent results in cutting molds with sheet adhesion and spin onto the surface

- Suitable for metal injection molds thanks to high oxidation resistance

- Suitable for plastic injection molds thanks to its superior surface properties

| Technical Properties | |

| Color | Silver Grey |

| Composition | CrN Based> |

| Oxidation temperature | 700 °C |

| Hardness | 2400 HV |

| Friction co-efficient | 0,35 |

| Coating thickness | 2 – 10 μm |