Expectations of production at high speed in the mold sector require the development of more wear-resistant mold materials, processes and coatings.

Increasingly difficult working conditions raise the requirement for coatings. This requirement is shaped depending on the following conditions:

- Especially in the automotive and white appliances sectors, the use of sheets with higher strength and corrosion resistance has become widespread.

- Press speeds has been increased for faster production

- The number of steps is reduced in progressive molds; that is, the amount of deformation in the part increases at each stage. This is a factor that increases the speed of wear

- Due to environmental factors, lubricants are restricted and as a result of this, lubrication amount and efficiency are reduced.

In general, high surface hardness, high wear resistance and low surface friction co-efficient are aimed by applying PVD coating on spinning, form, deep drawing and cutting-punching molds. There is no single type of coating that meets all these expectations at the same time. For this reason, the press properties, the type of the mold steel, the properties of the sheet metal to be used, the lubrication conditions of the press and the predominant wear characteristics of the mold parts should be examined and which type of coating is more suitable should be determined according to these findings.

General wear-damage mechanisms occurring in cold work mold parts and coating properties that should be preferred according to these mechanisms are summarized in the side-table.

| Failure mechanism | Predominant property expected from the coating | |

|---|---|---|

| Abrasive Wear (Scratch, picking, wear in free surface, atrophy in sharp corners) |  | High hardness and toughness |

| Adhesive wear (Winding, spinning, adhesive wear in free surface, workpiece adhesion to sharp corner) |  | Low friction co-efficient, high surface greasiness |

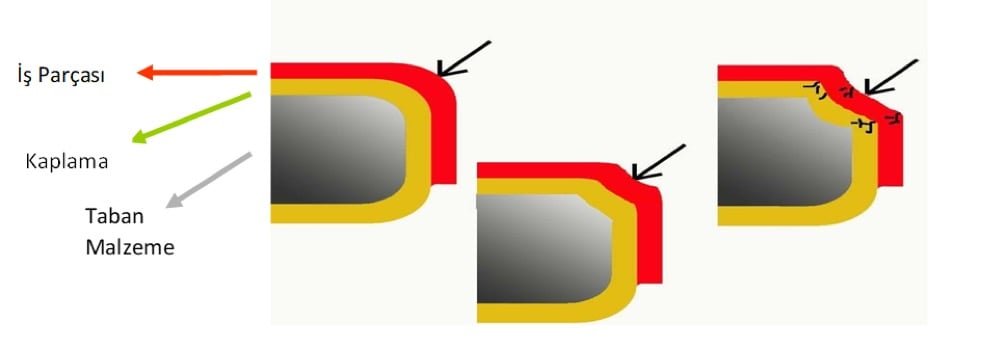

| Mouth spillage, scoring, fracture |  | High toughness and hardness, proper thermal treatment prior to coating |

| Plastic deformation (Chane in shape, fracture, mass damage) |  | Toughness, mold steel, hardness and strength of which is high, and coating selection, proper thermal treatment prior to coating |